Riri Group is pleased to present its new static galvanic system, recently installed in the Padua plant. The use of modern and innovative technologies allows for maintaining and constantly improving high quality standards, while always guaranteeing respect for the environment.

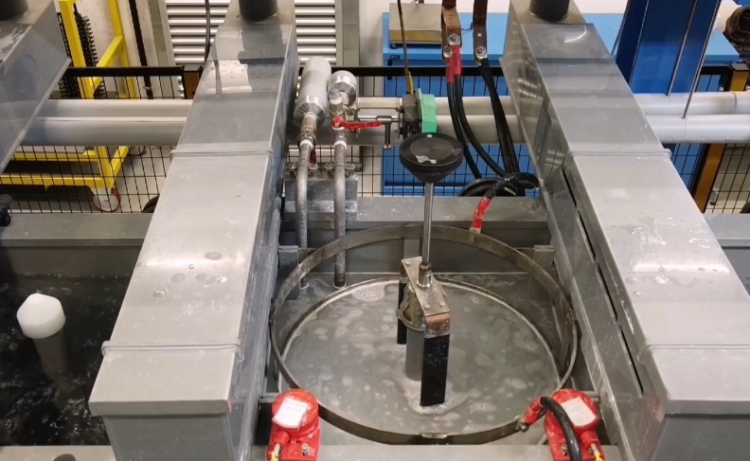

The structure includes 80 positions, 5 lines and 7 gantry cranes to move the frames. Among the strengths of the circular rotating frame installation, there is the possibility to ensure greater uniformity of thickness deposition and the opportunity to process, in addition to brass, materials such as Zamak and stainless steel; different colouring and deposition of gold, palladium and ruthenium can also be implemented.

The setting and control of all parameters, including temperature, current, dosage and Ph detection, occurs automatically.

The advanced tank heating system, using temperature controllers, leads to a significant performance improvement in terms of economic savings and safety, compared to systems with electrical resistance. In addition, considerable saving of water resources is guaranteed thanks to the re-circulation water purification system.

For more details, take a look at our new video: